RTGMS

Alternative to

Gas Chromatograph

Product Overview

Product Overview

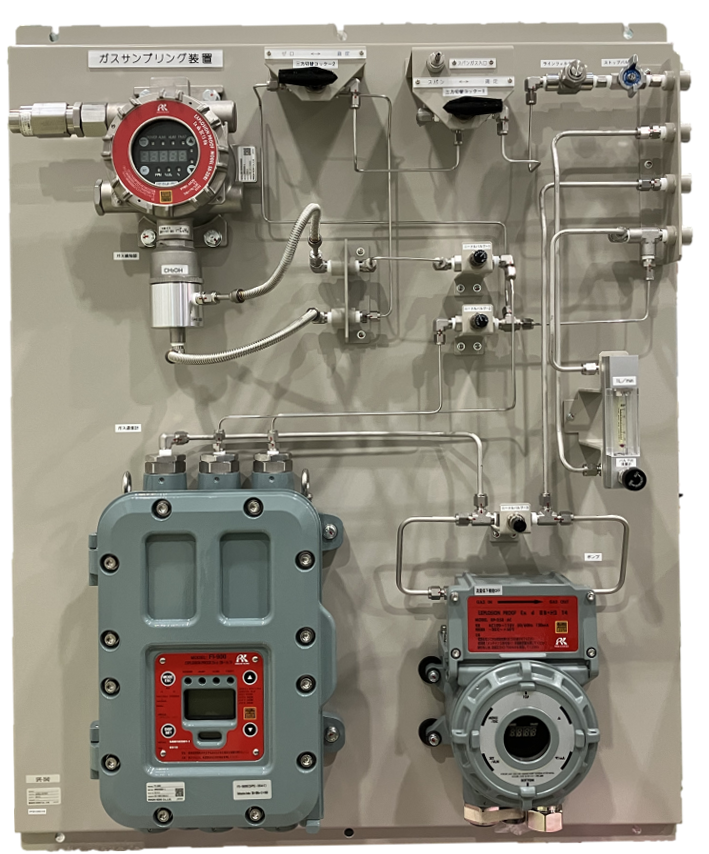

RTGMS is a tailored gas monitoring system for real-time measurement of high-concentration component gases.

By using multiple gas detection principles, RTGMS allows you to get accurate readings on multiple component gases even in environments under various constraints.

Product Overview

By using multiple gas detection principles, RTGMS allows you to get accurate readings on multiple component gases even in environments under various constraints.

Key Technologies

This approach ensures long-term accuracy, extended sensor life, and greatly reduced maintenance needs.

.png)

- RTGMS uses only reliable physical sensors, used and trusted by customers for over 10 years.

- Explosion-proof construction allows for installation as close as possible to the detection point, allowing for faster measurement times.

- We can design RTGMS optimized specifically for your work environment, allowing you to keep product costs to a minimum.

- Incredibly simple to use, implementing our RTGMS can result in significant reductions in time required for training and labor.

A wide variety of compatible sensors allows flexible system configuration.

By combining different sensor types according to the application, RTGMS can be tailored precisely to each customer’s process and environment.

-

Methanation process Control

-

Ammonia synthesis and decomposition monitoring

-

Hydrogen and natural gas co-firing gas turbine management

-1.png)

Additional Highlights

test

test

Specifications

| Product Name | RTGMS | |||

|---|---|---|---|---|

| Product Image |

|

|||

| Product Subtitle | Gas Analyzer | |||

| Product Type | Fixed Gas Analyzer | |||

| Industries | Infrastructure, Sustainable Energy, Steel | |||

| Use Purpose | Concentration management | |||

| Single/Multi | Multi | |||

| Certification | IECEx, ATEX, etc.(dependsonthespecification) | |||

| Detectable Gas | Mixed gases such as -CO, CO2, H2, CH4 and N2 Mixed Gas -Natural Gas + Hydrogen Mixed Gas -H2, CH4 and CO2 Mixed Gas -N2, H2 and NH3 Mixed Gas -Mixed Solvents | |||

| Detection Range | Customizable | |||

| Principle of Detection |

Customizable | |||

| Sampling Method | External Sampling Device | |||

| Ingress Proof Rating |

N/A | |||

| Dimensions | Depends on the Customization | |||

| Weight | Depends on the Customization | |||

| Remarks | ||||

| Power Source | 100 to 240 VAC±10 %, or 24 VDC ±10 % | |||

| Continuous Operation |

Depends on the Customization | |||

| Operating Temperature Range |

Depends on the Customization | |||

| Operating Humidity Range |

Depends on the Customization | |||

| Applicable Instruments |

Expert Support Awaits – Get in Touch Today!

Related Industries

You may also be

interested in

Gas Monitoring for a More Sustainable Society

Riken Keiki aids sustainability with gas monitors, supporting circular economy efforts and eco-friendly manufacturing practices.

Riken Keiki's OHC-800 Gas Calorimeter: Demonstrating High Accuracy in a Technology Verification Project by Japan's Digital Agency

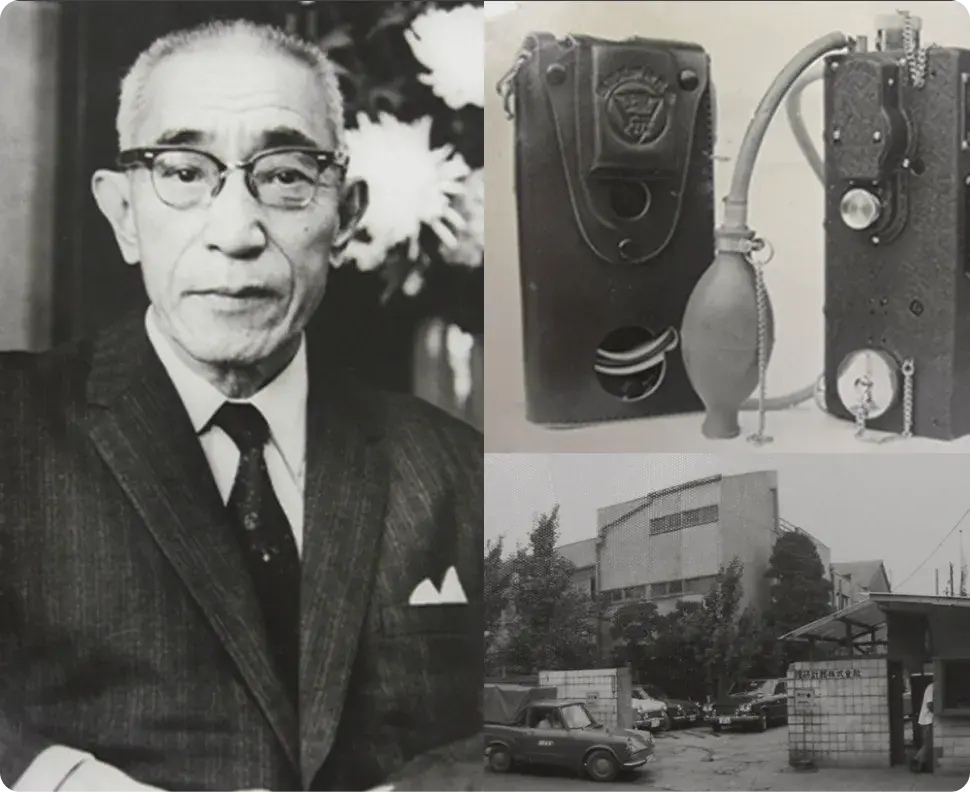

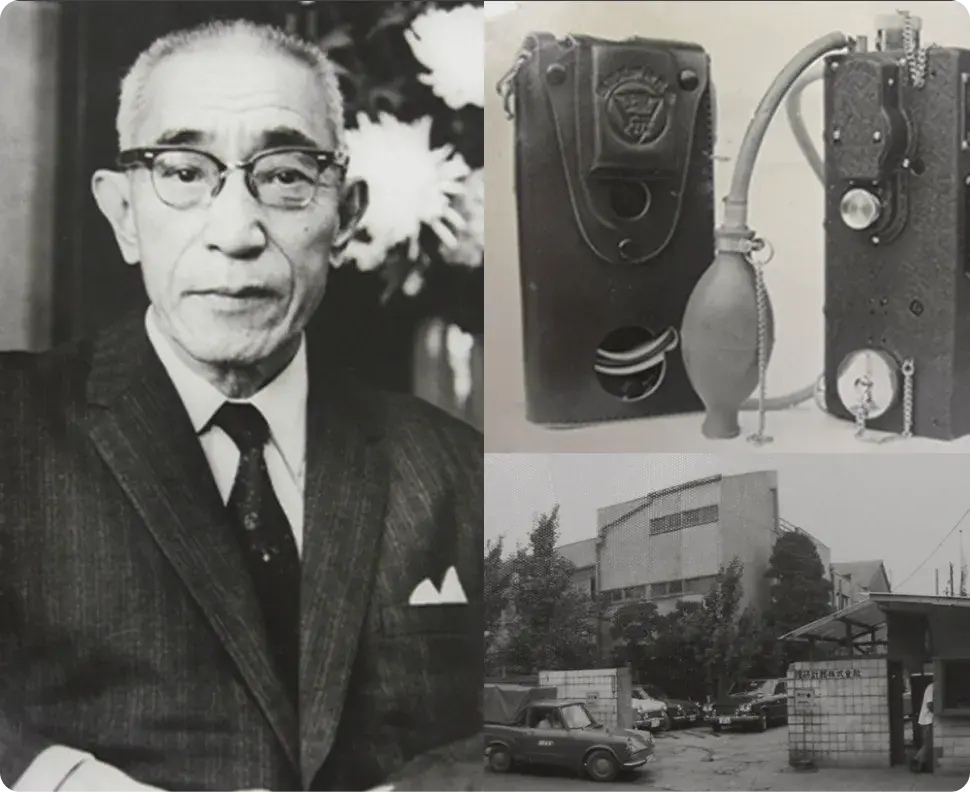

Riken Keiki, a pioneer in industrial gas detection since 1939.

Solutions for Efficient Methanation

Methanation creates methane from CO₂ and hydrogen, offering a cleaner energy source while highlighting the need for precise gas monitoring.

Why Customers Choose Us

Since our beginnings in 1939, Riken Keiki has continued to lead the way in gas detection technology, laying the foundations that support our modern society.

Discover why customers continue to choose Riken Keiki, the global standard in gas detection equipment.

Since our beginnings in 1939, Riken Keiki has continued to lead the way in gas detection technology, laying the foundations that support our modern society.

Discover why customers continue to choose Riken Keiki, the global standard in gas detection equipment.

See Our Solutions in Action!

See Our Solutions in Action!