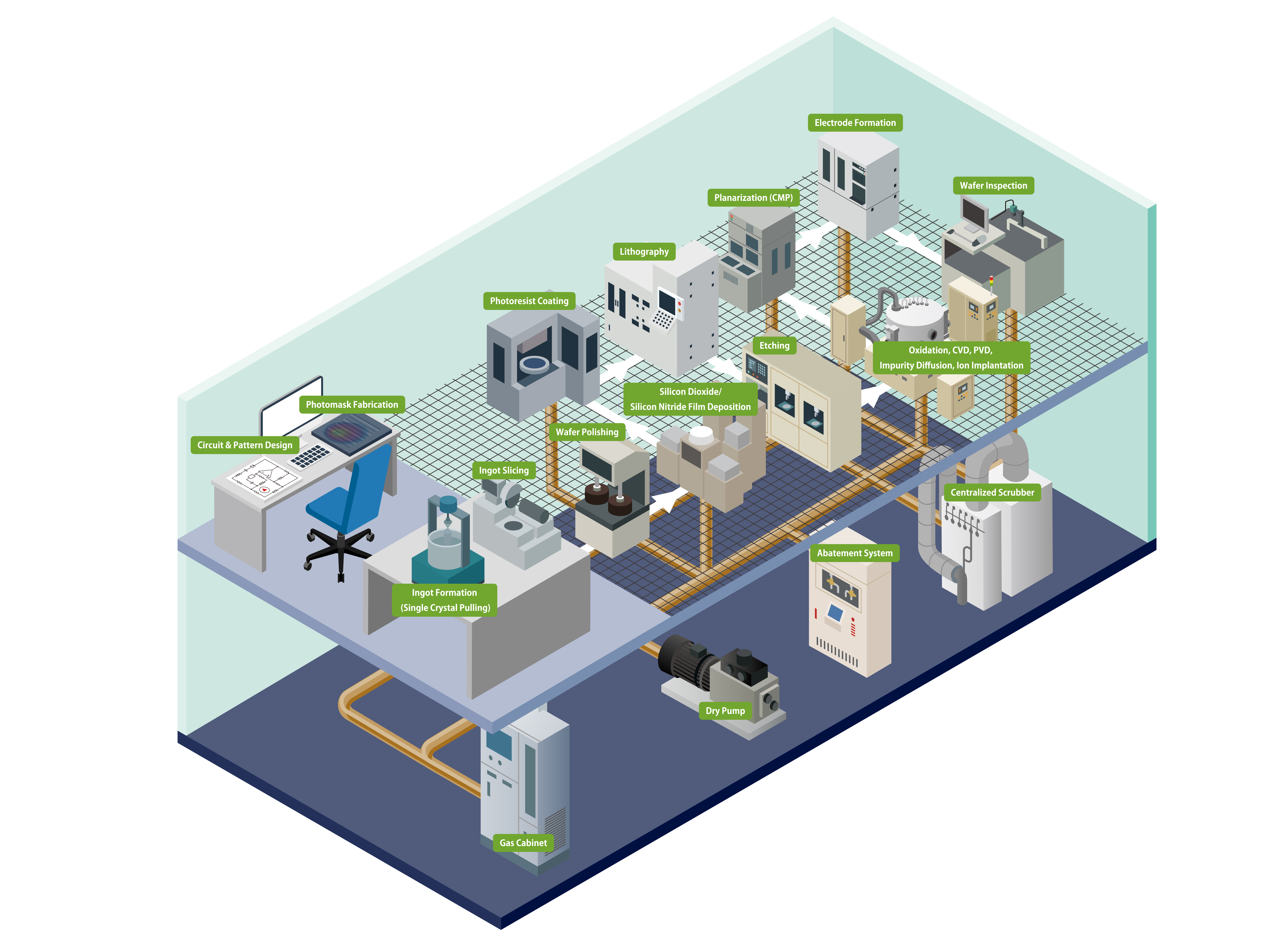

Semiconductors

Used in smartphones, computers, automobiles, and IoT devices, semiconductors are integral to modern digital technologies.

Semiconductor manufacturing is different from other industries in that it requires the use of gases with specific compositions and purities, tailored to meet the unique requirements of each process.

As semiconductor manufacturing continues to expand in response to evolving digital technologies, the processes involved are likewise becoming increasingly complex.

Advanced Detection of a Wide Range of Gases

Safety management in semiconductor manufacturing requires detecting various gases, including toxic and combustible gases. Riken Keiki offers a wide range of products that are suitable for TLV (Threshold Limit Values) management, protecting the safety of workers while addressing the diversity of gases used in semiconductor manufacturing.

Diverse Gas Detection Solutions for the Semiconductor Industry

We provide gas detection systems that cover a wide variety of gases, such as:

・Suction-type Gas Detectors - More than 260 types of gas sensors are available, including semiconductor material gas sensors, hydrogen sensors, and interference-resistant sensors. The unit structure ensures excellent maintenance capabilities. (Compatible Products: GD70 Series)

・Portable Gas Leak Detectors - Large pump-equipped gas detectors capable of simultaneously measuring three toxic gases are available, along with devices that can detect up to 50 types of semiconductor material gases with a single unit. These products are ideal for detecting gas leaks in semiconductor factories.

Our solutions are customizable to reduce both initial and maintenance costs by recommending the optimal number of portable gas detectors for the gases used. (Compatible Products: 04 Series, SC-9000, SP-230)

Our Solutions

We don't just provide detectors — we design and manufacture our own sensors in house. This approach ensures that we can promptly respond to the emergence of new gases by conducting sensor sensitivity studies and developing new sensors based on customer requirements.

Currently, we have already developed over 260 types of sensors and continue to advance sensor development to detect new gases in the future.

No. 1 Market Share in Japan

In Japan, which has long supported the global semiconductor market, RIKEN KEIKI holds the No.1 market share for gas detectors used in semiconductor applications. Our products are highly regarded in the semiconductor industry and research fields, with annual sales exceeding 40,000 units. Trusted for their high performance, our gas detectors are widely adopted in the semiconductor sector around the world, ensuring safe and reliable gas leak monitoring.

Supporting the Semiconductor Industry, Domestically and Worldwide

Headquartered in Japan, RIKEN KEIKI not only holds a dominant market share domestically but has also established a strong global presence.

In Taiwan, a major hub for semiconductor production, we have delivered a total of over 90,000 units, while shipments to South Korea and China have reached 25,000 and 220,000 units respectively. Our distribution network continues to expand worldwide.

Gas detectors require regular professional maintenance, including calibration and adjustment. To support this, RIKEN KEIKI has a global network of distributors, ensuring prompt maintenance services and efficient supply of products and parts to manufacturing sites around the world.

Expert Support Awaits – Get in Touch Today!

Environmental Monitoring with High-Sensitivity Sensors

Some of the gases used in semiconductor manufacturing can be hazardous even at extremely low concentrations. Some gases like monosilane are toxic to humans even in trace amounts, and others like phosphine pose a risk of spontaneous ignition, potentially leading to fires.

Therefore, highly precise gas detection is essential for effective gas leak monitoring in semiconductor facilities. RIKEN KEIKI offers detectors capable of identifying specific gases at some of the lowest detection limits in the industry, enabling optimal TLV (Threshold Limit Value) management tailored to each gas.

High Sensitivity for Early Detection

We offer ultra-sensitive toxic gas monitors using a tape detection system. The tape-based detection part provides a visual confirmation of whether the gas has leaked, by changing color.

Our products can detect gases even at extremely low concentrations, allowing for the detection of gases at the ppb level. They can selectively detect trace amounts of toxic gases for early detection without interference from other gases. (Compatible Product: FP-300)

Related Products

.png)

You may also be

interested in

The Importance and Key Considerations of IP Codes When Choosing Gas Detectors

Learn why IP codes matter when choosing gas detectors. Discover how dust and water resistance ensure reliable performance and worker safety in harsh environments.

Heavy Fuel Oil and LNG

Heavy fuel oil powers global shipping with efficiency, affordability, and safety—maximizing cargo space and enabling long-distance voyages.

Gas Monitoring Considerations When Using Ammonia as a Fuel

Ammonia may be key to net-zero goals as a CO₂-free energy source, aiding the shift from fossil fuels to cleaner alternatives.