Optimize Calorimetry &

Process Control

Key Features

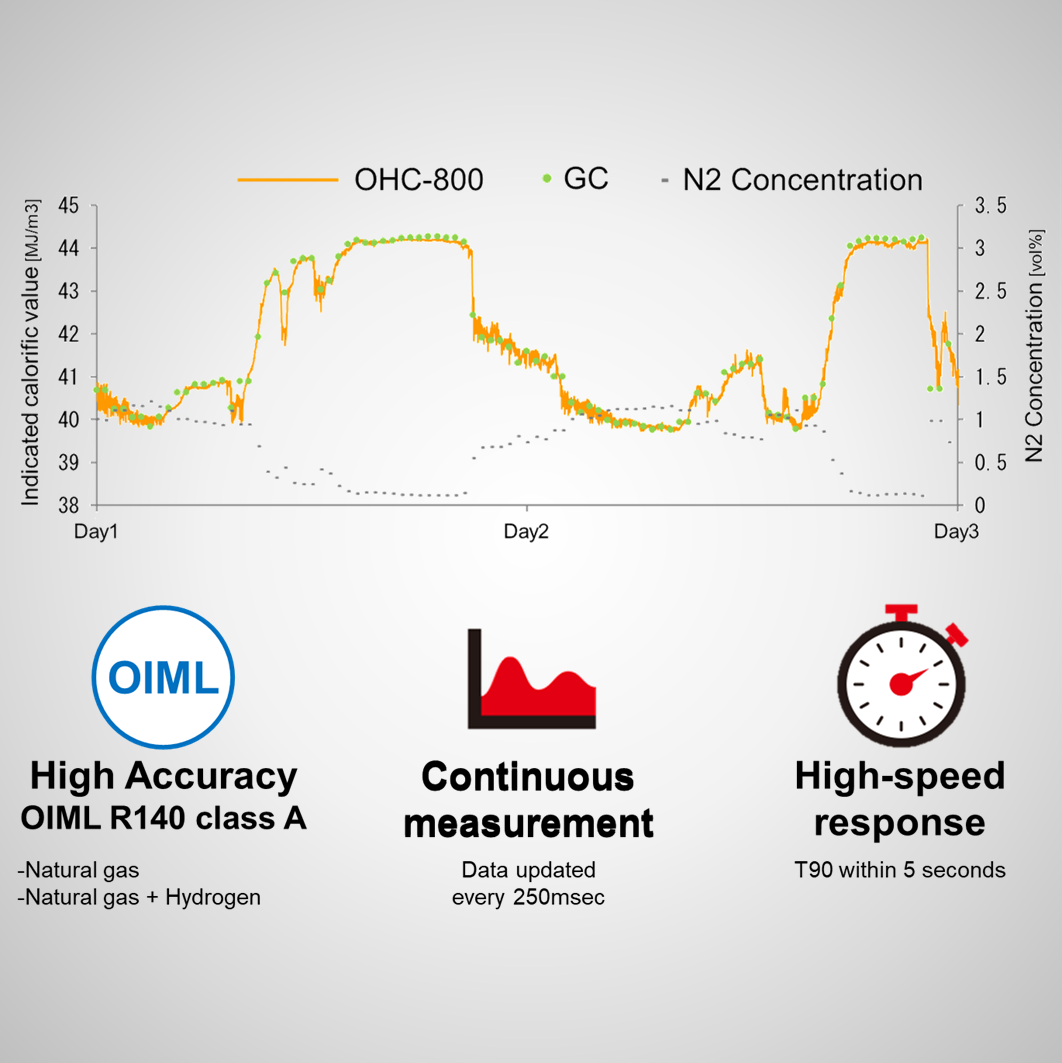

The OHC-800 uses physical sensors rather than chemical reactions, eliminating the use of consumables and therefore the need for ongoing internal maintenance. (Regular verification of indicated values using standard gas is recommended.) Its physical sensors provide lasting stability without loss of sensitivity over time, and have even been known to last as long as 10 years before replacement.

Hydrogen

Natural gas with hydrogen

Steel gases (COG, BFG, LDG)

Flare gas

E-methane

Renewable natural gas

Biogas

Methanation gas

Additional Highlights

Robust design

A robust product design that can withstand harsh environments, eliminates the risk of sudden measurement outages.

・Operating temperature: -20 to 57℃

・IP: equivalent to IP66/67

・ATEX/IECEX/FM/ etc.

Customizable

We are able to customize a single unit to meet customer's requirements for measuring gases and applications.

Please contact us for more information.

Space saving

Expert Support Awaits – Get in Touch Today!

Specifications

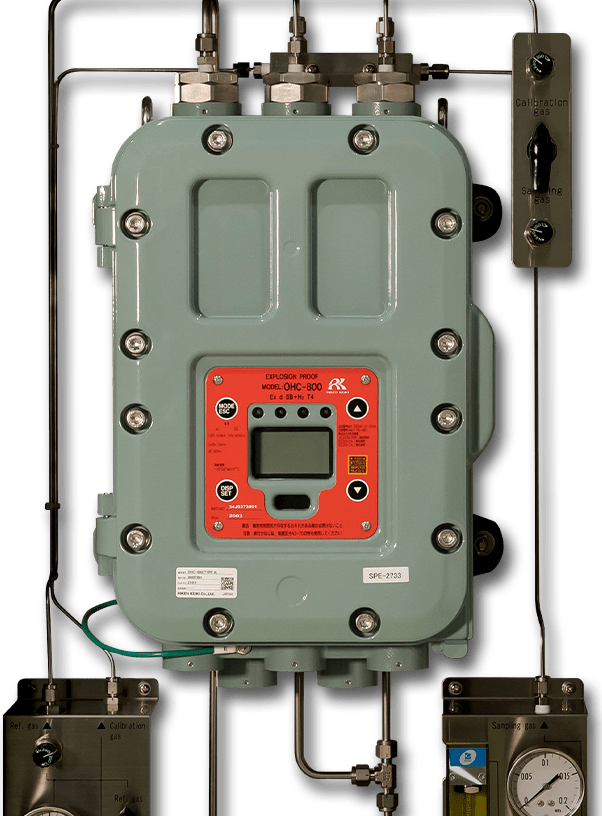

| Product Name | OHC-800 | |||

|---|---|---|---|---|

| Product Image |

|

|||

| Product Subtitle | Explosion-proof Calorimeter | |||

| Product Type | Fixed Gas Analyzer | |||

| Industries | Infrastructure, Sustainable Energy, Marine, Oil & Gas, Steel | |||

| Use Purpose | Measure Calorific value | |||

| Single/Multi | Single | |||

| Certification | Japanese Certification, IECEx, ATEX, China Ex (China), FM (USA, Canada), etc.(dependsonthespecification) | |||

| Detectable Gas | Fuel gases such as Natural Gas, COG, BFG, LDG, LPG, Natural Gas with Hydrogen, Flare Gas, Methane, Natural Gas with LPG, Boil-Off Gas, E-Methane, Renewable Natural Gas, Off-Gas from Refinery, Butane, Biogas, Methanation Gas, Low Calorie Gas, Biogas with LPG, Hydrogen | |||

| Detection Range | Calorific Value : 25.00 to 50.00 MJ/m3 (Gross 0℃, 101.325 kPa Converted) Density : 0.500 to 1.500 (specific gravity converted) |

|||

| Principle of Detection |

N/A | |||

| Sampling Method | External Sampling Device | |||

| Ingress Proof Rating |

IP 66/67 | |||

| Dimensions | Approx. 286(W)× 453(H)× 150(D) mm | |||

| Weight | Approx. 23 kg | |||

| Remarks | ・Self-Diagnostic Function ・Easy to Switch the Display Among “Calorific Value”, “Density” and “WOBBE Index” | |||

| Power Source | 100 to 240 VAC±10 %, or 24 VDC ±10 % AC/DC Switchable in the Setting Mode | |||

| Continuous Operation |

N/A | |||

| Operating Temperature Range |

-20 to +60 ℃ (no sudden changes) | |||

| Operating Humidity Range |

0 to 95 %RH (no condensing) | |||

| Applicable Instruments |

Related Industries

You may also be

interested in

Gas Monitoring for a More Sustainable Society

Riken Keiki aids sustainability with gas monitors, supporting circular economy efforts and eco-friendly manufacturing practices.

Riken Keiki's OHC-800 Gas Calorimeter: Demonstrating High Accuracy in a Technology Verification Project by Japan's Digital Agency

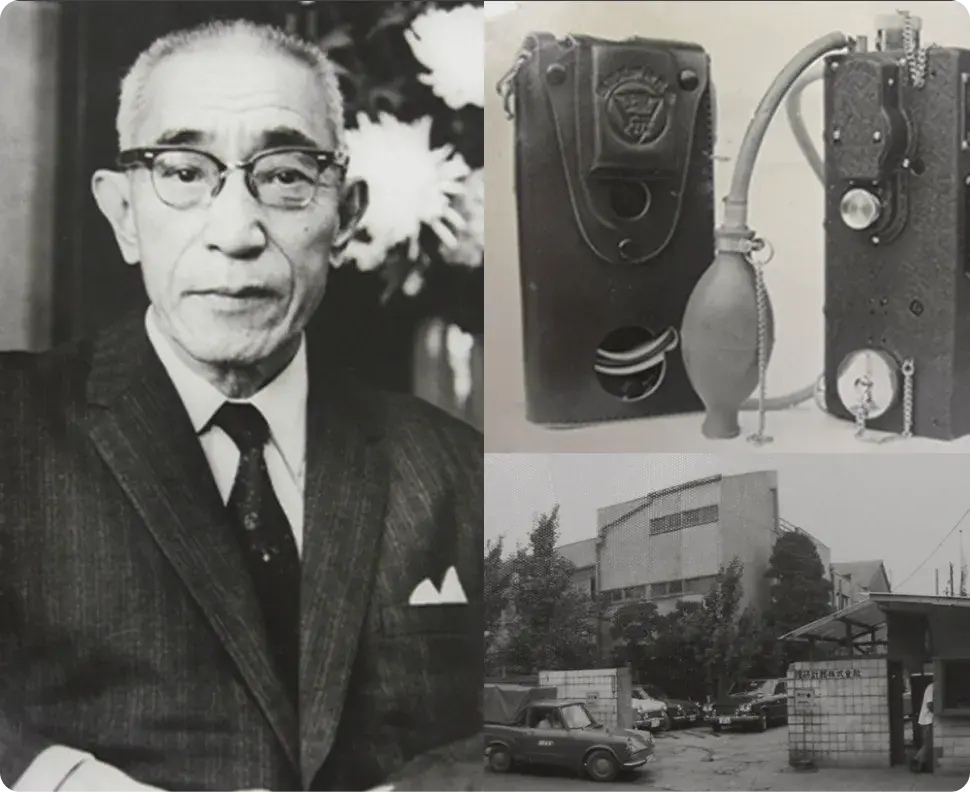

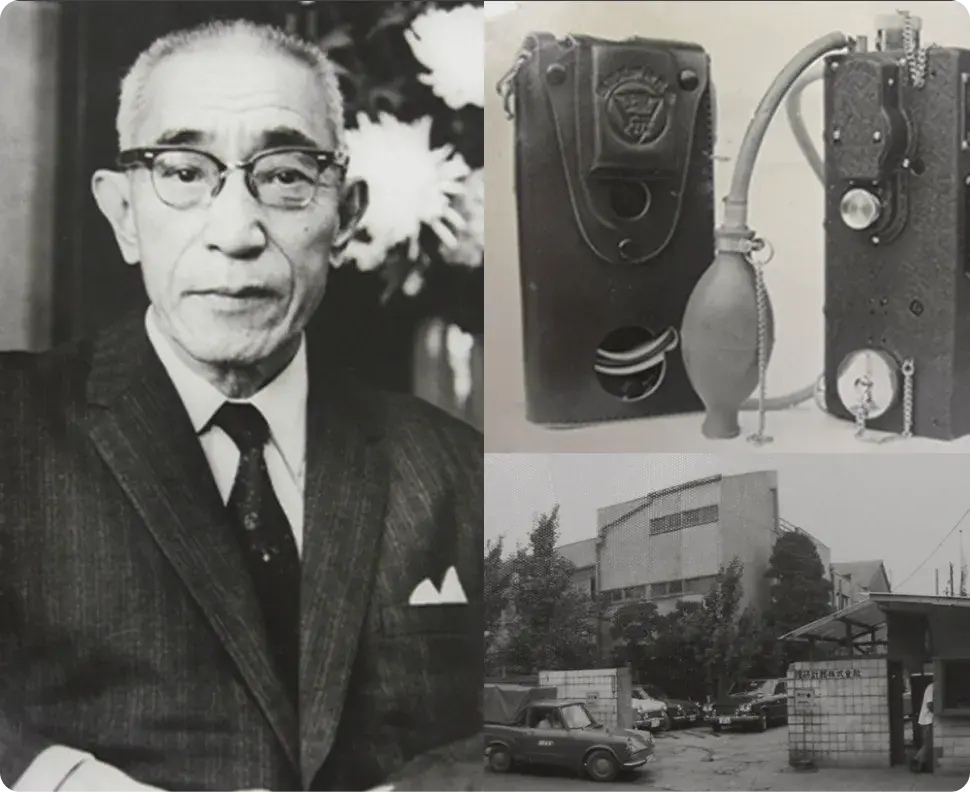

Riken Keiki, a pioneer in industrial gas detection since 1939.

Solutions for Efficient Methanation

Methanation creates methane from CO₂ and hydrogen, offering a cleaner energy source while highlighting the need for precise gas monitoring.

Why Customers Choose Us

Since our beginnings in 1939, Riken Keiki has continued to lead the way in gas detection technology, laying the foundations that support our modern society.

Discover why customers continue to choose Riken Keiki, the global standard in gas detection equipment.

See Our Solutions in Action!

See Our Solutions in Action!