Steel

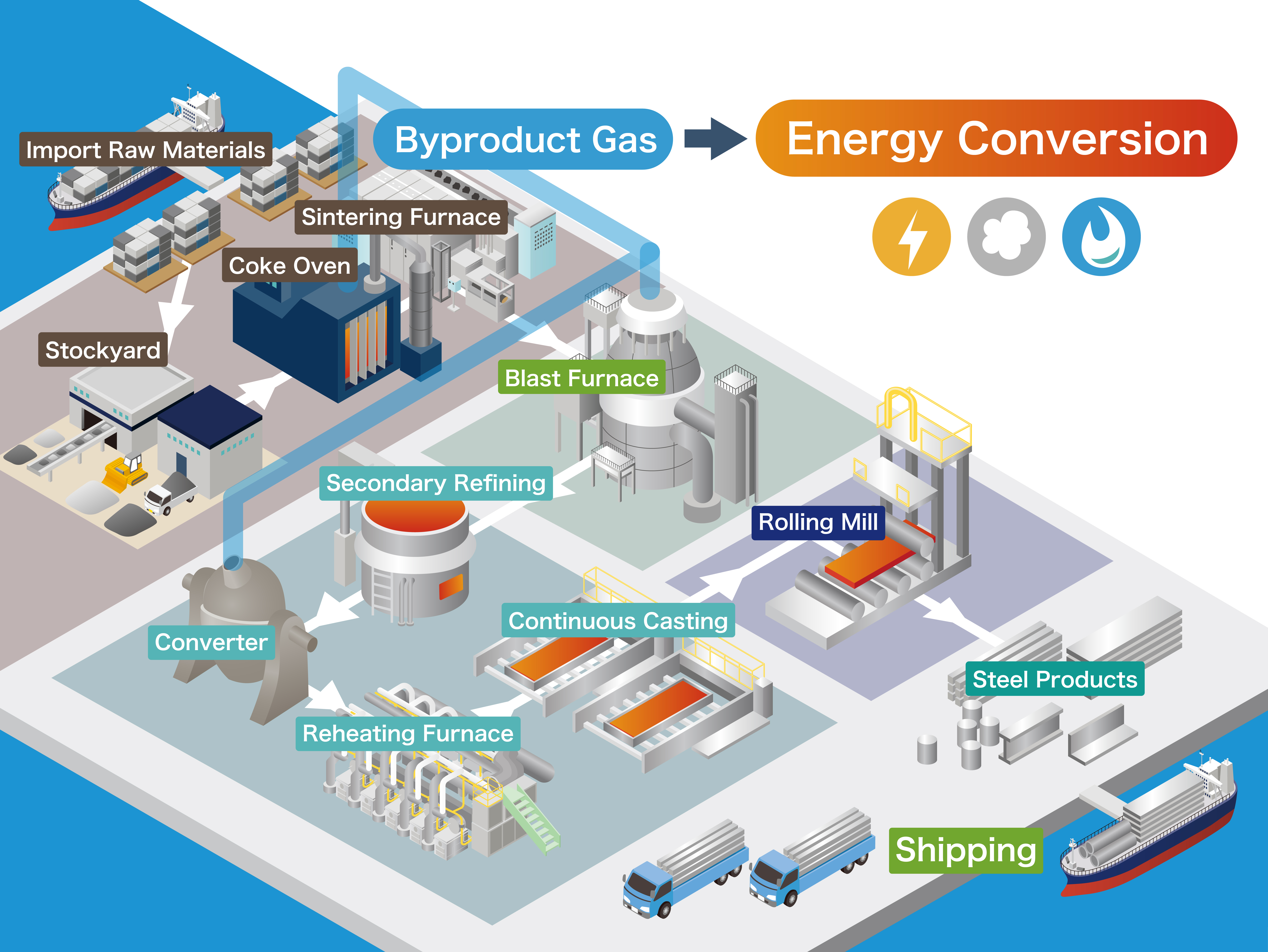

In steel manufacturing, the iron content in iron ore is reduced through contact with the carbon in coke, producing pig iron.

Various gases are given off throughout every step of the process, such as sintering, coke, and blast furnace processes.

Key aspects of gas monitoring include detecting toxic gases such as carbon monoxide and sulfur dioxide, even in small amounts, and reusing byproduct gases as an energy source.

Our Strengths

Development of Site-Specific Sensors / Comprehensive Worker Safety Enhancement

Steel plants can generate multiple toxic gases in various work areas. Riken Keiki's gas detectors can detect multiple gas components with a single device, reducing management costs and enhancing worker safety without increasing the number of devices used.

Streamlined Gas Detection for Superior Safety

We develop sensors and gas detectors optimized for the steel industry, including:

・Hydrogen Interference-Resistant CO Sensor:

In conventional CO detection, hydrogen in the gas composition would react with the CO sensor, leading to false alarms. We've developed a proprietary sensor that detects CO accurately, even in the presence of 500 ppm hydrogen, ensuring reliable monitoring.

・Multi-Gas Detection Including SO2:

Dedicated SO2 gas detectors can be costly and cumbersome for workers to wear. Our gas detectors can detect multiple components—including hydrogen, methane, hydrogen sulfide, carbon monoxide, oxygen, carbon dioxide, and sulfur dioxide (SO₂)—all in one device. This helps lower management costs and improve worker safety while keeping the number of devices to a minimum.

Reliable Performance in Harsh Environments

The steel industry often involves extreme conditions, such as high temperatures, high humidity, and the presence of iron dust and ore powder, requiring exceptionally durable products in certain environments. We develop sensors and conduct safety experiments in-house while complying with various standards and obtaining international certifications. Our products are designed to withstand harsh environments and perform reliably in the field.

Certified Tough. Built for the Field.

・IP66/68 (Dust-tight / Protection against continuous immersion in water and powerful water jets)

・Drop Durability (7m / 1.5m, etc.)

・Operating Temperature (-20℃ to 50℃, short-term*: -40℃ to 60℃)

*Approx. 15 minutes

・Explosion-Proof Compliance<br><br>・Standard 3-year warranty

*Specifications may vary by model. Please contact us for details.

Expert Support Awaits – Get in Touch Today!

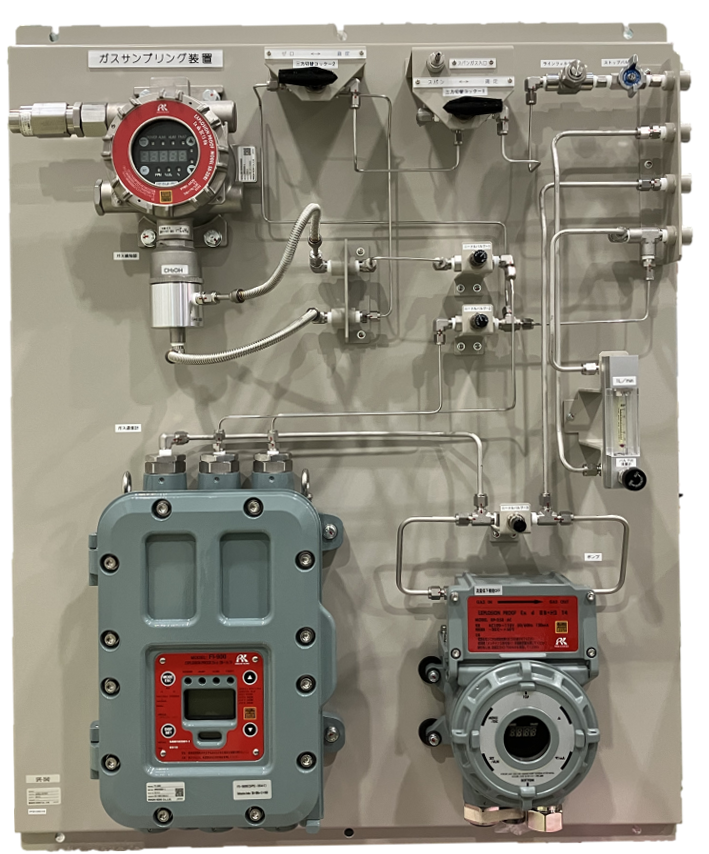

Comprehensive Product Portfolio for Various Applications

Gas measurement in the steel industry requires a wide range of applications, each demanding specific gas detection solutions. We provide a comprehensive range of gas detectors for steel manufacturing, including industry-specific applications, helping to eliminate the complexity of device and maintenance management.

Powerful Solutions for Every Application

Here are some of the powerful gas detection solutions we offer:

・CO Gas Detection in Hard-to-Wire Locations, such as worker pathways in ladle facilities.

・Gas detector equipped with a CO sensor that reduces hydrogen interference.

・Multi-gas detector that can be equipped with an SO2 sensor.

・Smoldering Fire Detection: Early fire prevention through CO monitoring.

・Calorific value measurement for byproduct gas reuse

・Oxygen detection with 3-step alarm (L-LL/H)

・Ammonia detection for DeNOx systems

・CO monitoring around boilers

Riken Keiki offers a wide range of solutions tailored to meet diverse gas detection needs.

If you're facing challenges with gas detection, reach out to us for an effective solution.

Related Products

.png)

You may also be

interested in

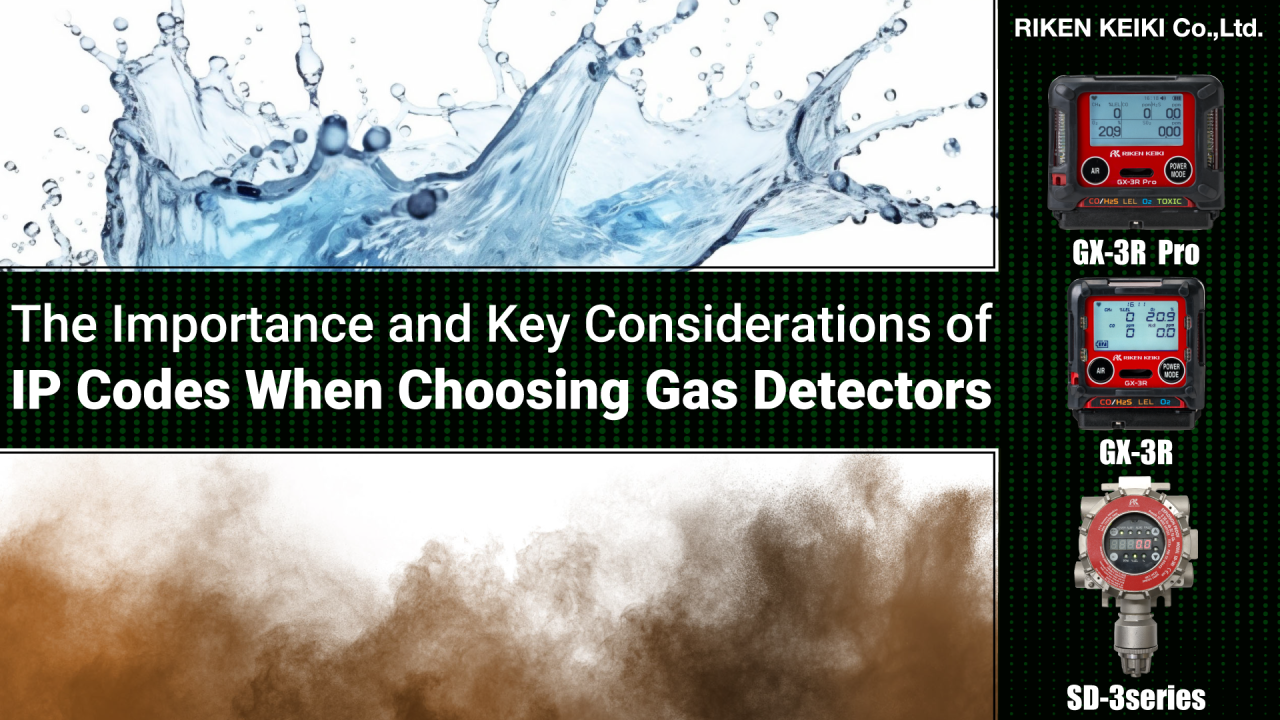

The Importance and Key Considerations of IP Codes When Choosing Gas Detectors

Learn why IP codes matter when choosing gas detectors. Discover how dust and water resistance ensure reliable performance and worker safety in harsh environments.

Heavy Fuel Oil and LNG

Heavy fuel oil powers global shipping with efficiency, affordability, and safety—maximizing cargo space and enabling long-distance voyages.

Gas Monitoring for a More Sustainable Society

Riken Keiki aids sustainability with gas monitors, supporting circular economy efforts and eco-friendly manufacturing practices.