Understanding Flammable Gases and Their Hazards: Ensuring Worker Safety with Gas Detectors

Table of Contents

Definition of Flammable Gases

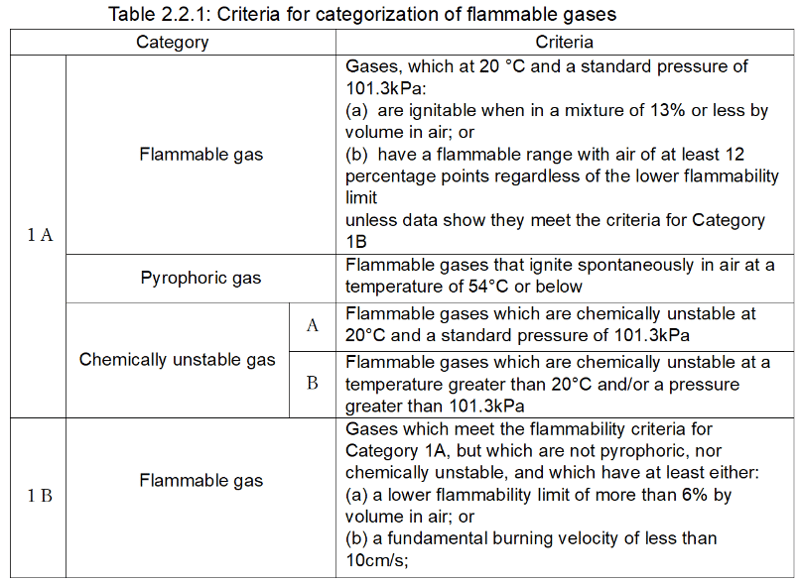

The international standard for flammable gases is defined in the United Nations GHS document as "a gas having a flammable range with air at 20°C and a standard pressure of 101.3 kPa."

The following is an excerpt from the United Nations GHS document:

2.2.2.1 A flammable gas is classified in Category 1A, 1B or 2 according to the following table. Flammable gases that are pyrophoric and/or chemically unstable are always classified in Category 1A.

Types of Flammable Gases and Their Hazards

Methane

Hydrogen

Propane (Gas)

Markets Related to Flammable Gases

Production: Oil & Gas

The oil & gas industry involves the extraction and production of fuels like kerosene, diesel, and gasoline, as well as flammable gases like propane and butane. These are used as raw materials in various products and as energy sources supporting industries. As a result, the oil & gas industry is indispensable to global industries and everyday life. And due to the high flammability of these products, the oil & gas industry is one of the sectors that requires stringent management of flammable gases.

Additionally, one of the most hazardous gases in this industry is hydrogen sulfide. It is released during various processes such as mining and refining. Hydrogen sulfide is not only highly flammable but also extremely toxic, posing a significant danger. Even in small amounts, inhalation can lead to disorders of the central nervous system, cardiovascular system, and respiratory system.

To protect workers from these threats, it is essential to install gas detectors in areas where gases may be present, and to provide portable detectors for workers to carry.

Transportation: Shipping

Flammable gases generated in the oil & gas industry must be distributed from refining facilities for use in various industries and households. Ships play a crucial role in the transportation process, with LPG tankers being a prime example.

LPG is a liquefied form of propane or butane, achieved through compression or cooling. If LPG leaks for any reason, there is a risk of explosion. A fire incident involving a tanker can cause significant damage not only to the ship and workers, but also to port facilities and marine resources. To prevent such accidents, stringent gas management using fixed and portable gas detectors is necessary.

Generation: Steel manufacturing

In the steel manufacturing industry, flammable gases are generated during many processes leading up to the completion of products. For example, in the steel manufacturing process, where iron ore, coal (coke), and limestone are burned, gases such as carbon monoxide and hydrogen are produced. Additionally, high concentrations of carbon monoxide and hydrogen are generated during the blast furnace process of producing pig iron, while carbon monoxide is also produced during the converter and secondary refining processes.

If these gases leak during any of the processes, they can cause fires, explosions, or carbon monoxide poisoning, depending on the working environment and concentration. However, they also have flammable properties. Therefore, they are safely recovered during the processes and recycled as fuel gases.

Protecting Workers: Our Gas Detection Solution

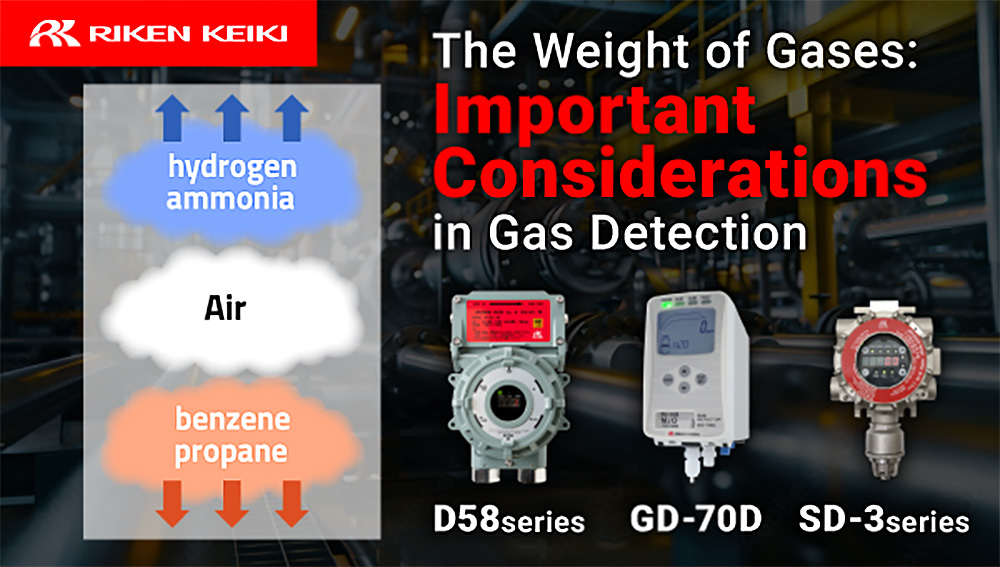

To protect workers, it is crucial to properly detect and strictly manage flammable gases. Here are three of our products designed to protect workers from flammable gases.

GX-Force is a high-performance gas detector with an integrated pump, ideal for pre-measurement in confined spaces. In such spaces, there is a risk of oxygen deficiency and accumulation of toxic or flammable gases, so pre-measurement before work is crucial to prevent accidents. GX-Force can measure the concentration of 27 types of flammable gases, including hydrogen, and allows you to preset the gas you want to measure. In addition, you can detect gas leaks with the supplied nozzle. After measurement, you can remove the suction tube and attach the small, unobtrusive main unit to the breathing zone enabling real-time safety management during work.

PRODUCTS

Product type |

Portable Gas Detector |

|---|---|

Applications |

|

single/multi |

Multi |

Product type |

Portable Gas Detector |

|---|---|

Applications |

|

single/multi |

Multi |

Product type |

Portable Gas Detector |

|---|---|

Applications |

|

single/multi |

Multi |

Product type |

Fixed Gas Detector |

|---|---|

Applications |

|

single/multi |

Single |

You may also be

interested in

Want to hear from an expert?

You may also be

interested in

The Importance and Key Considerations of IP Codes When Choosing Gas Detectors

Learn why IP codes matter when choosing gas detectors. Discover how dust and water resistance ensure reliable performance and worker safety in harsh environments.

Heavy Fuel Oil and LNG

Heavy fuel oil powers global shipping with efficiency, affordability, and safety—maximizing cargo space and enabling long-distance voyages.

Gas Monitoring for a More Sustainable Society

Riken Keiki aids sustainability with gas monitors, supporting circular economy efforts and eco-friendly manufacturing practices.

Publications