70D Series

.png)

.png)

70D Series

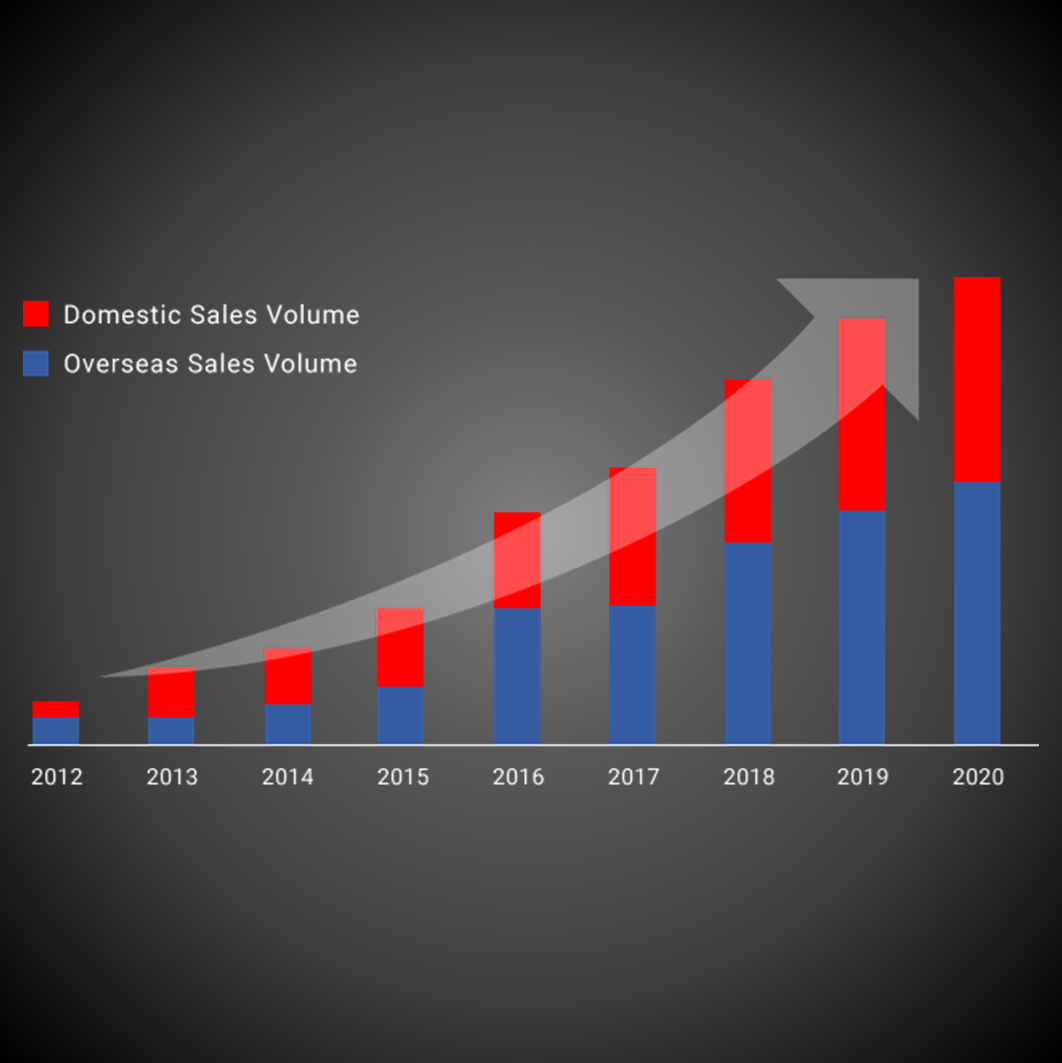

Our GD-70D Series is the best-selling gas detector in the Japanese semiconductor industry, testament to its unbeatable reliability and performance. Trusted also by the semiconductor industry and research facilities worldwide, this best-selling product boasts some 100,000 units in annual sales. Proven to meet the demanding performance needs of the global semiconductor and research industries, you can trust our GD-70D Series for your gas leak management needs.

Specifications

| Product Name | GD-70D | TP-70D | TP-70DGII | |

|---|---|---|---|---|

| Product Image |

.png)

|

|

|

|

| Product Subtitle | Fixed Gas Detector | Smart-Type Gas Detector Head | Smart-Type Gas Detector Head | |

| Product Type | Fixed Gas Detector | Fixed Gas Detector | Fixed Gas Detector | |

| Industries | Infrastructure, Semiconductors, Sustainable Energy | Semiconductors | Semiconductors | |

| Use Purpose | Safety management | Safety management | Safety management | |

| Single/Multi | Single | Single | Single | |

| Certification | CE Mark | CE Mark | ||

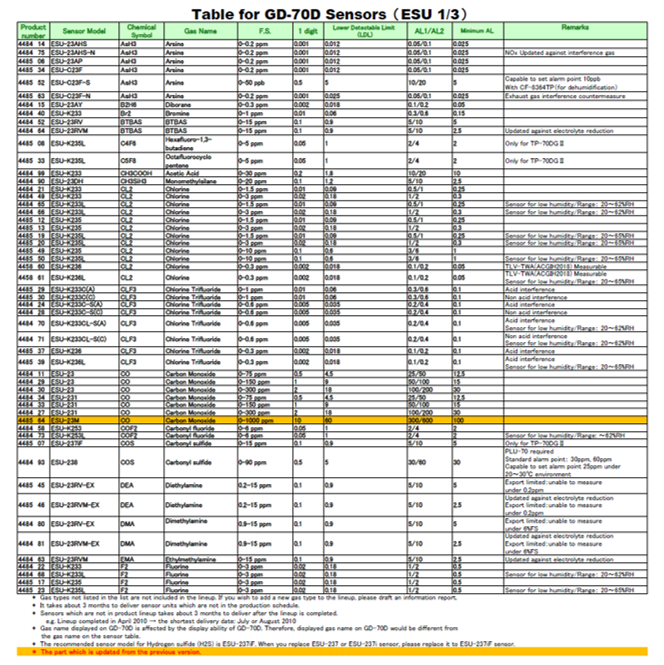

| Detectable Gas | Lineup of More Than 260 sensors | Lineup of More Than 100 Sensors | C4F6,C5F8,COS | |

| Detection Range | N/A | N/A | 0 to 5 ppm (C4F6)(C5F8) 0 to 15 ppm (COS) | |

| Principle of Detection |

New Ceramic Catalytic Method, Semi-Conductor Method, Hot Wire Type Semi-Conductor Method, Non-Dispersive Infrared Method, Potentiostatic Electrolysis Method, Membrane Type Galvanic Cell Method, Pyrolysis-Particle Detection Method | Catalytic Combustion Method, Semi-Conductor Method, Non-Dispersive Infrared Method, Potentiostatic Electrolysis Method, Membrane Type Galvanic Cell Method | Potentiostatic Electrolysis Method | |

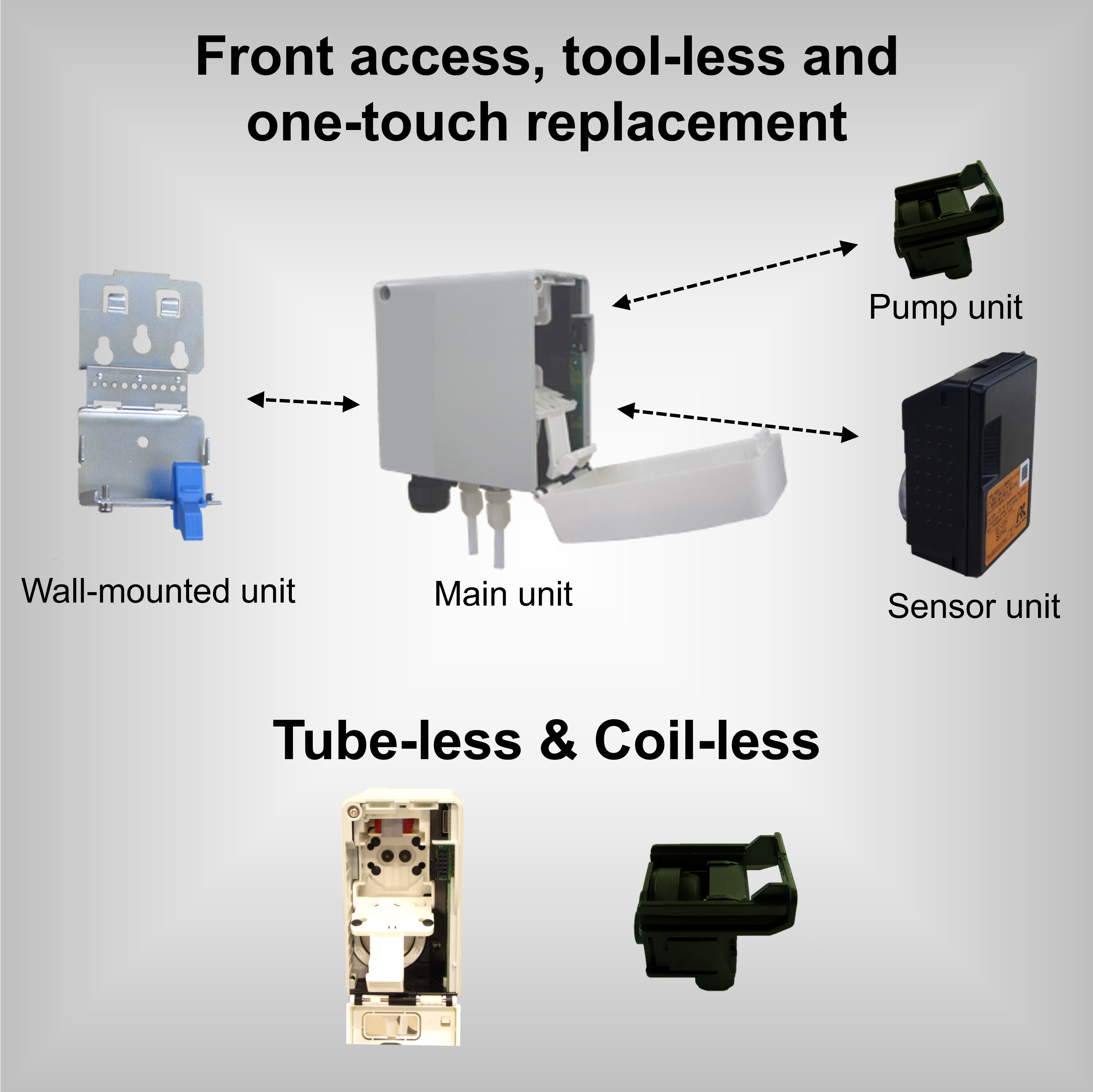

| Sampling Method | Internal Sample Pump | Internal Sample Pump | Internal Sample Pump | |

| Ingress Proof Rating |

N/A | N/A | N/A | |

| Dimensions | Approx. 70 (W) x 120 (H) x 145 (D) mm | Approx. 160 (W) x 210 (H) x 260 (D) mm (excluding projections) | Approx. 180 (W) x 225 (H) x 285 (D) mm (excluding projections) | |

| Weight | Approx. 0.9 kg | Approx. 4.3 kg | Approx. 6.0 kg | |

| Remarks | Self-diagnostic Function, Automatic Flow Rate Adjustment | Transportable, Automatic Flow Rate Adjustment | Transportable, Automatic Flow Rate Adjustment | |

| Power Source | 24 VDC ±10 %, POE | 100 V to 240 VAC ±10 % | 100 V to 240 VAC ±10% | |

| Continuous Operation |

N/A | N/A | N/A | |

| Operating Temperature Range |

0 to 40 ℃ (no sudden changes) | 0℃ to 40 ℃ (by the installed sensor unit, no sudden changes) | 20℃ to 40℃ (no sudden changes) | |

| Operating Humidity Range |

30 to 70 %RH (no condensation) | 30 to 70 %RH (no condensation) | 40 to 70 %RH (no condensation) | |

| Applicable Instruments |

Expert Support Awaits – Get in Touch Today!

Related Industries

You may also be

interested in

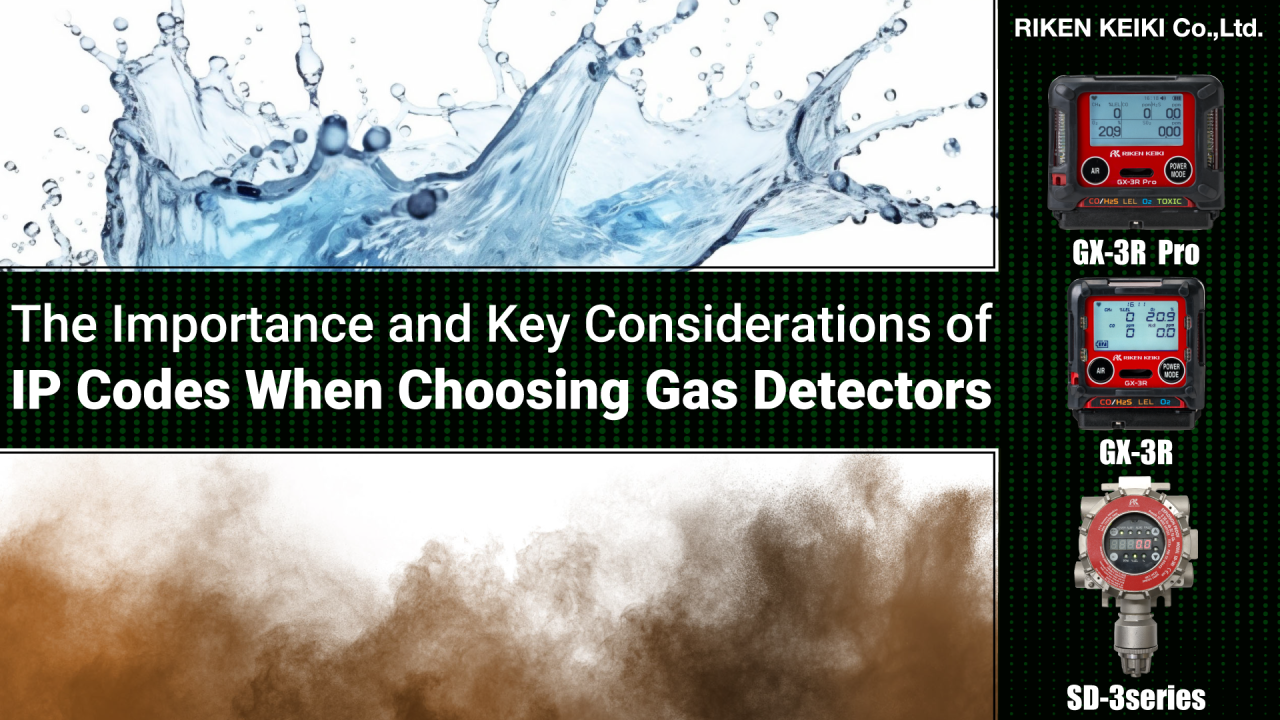

The Importance and Key Considerations of IP Codes When Choosing Gas Detectors

Learn why IP codes matter when choosing gas detectors. Discover how dust and water resistance ensure reliable performance and worker safety in harsh environments.

Heavy Fuel Oil and LNG

Heavy fuel oil powers global shipping with efficiency, affordability, and safety—maximizing cargo space and enabling long-distance voyages.

Gas Monitoring for a More Sustainable Society

Riken Keiki aids sustainability with gas monitors, supporting circular economy efforts and eco-friendly manufacturing practices.

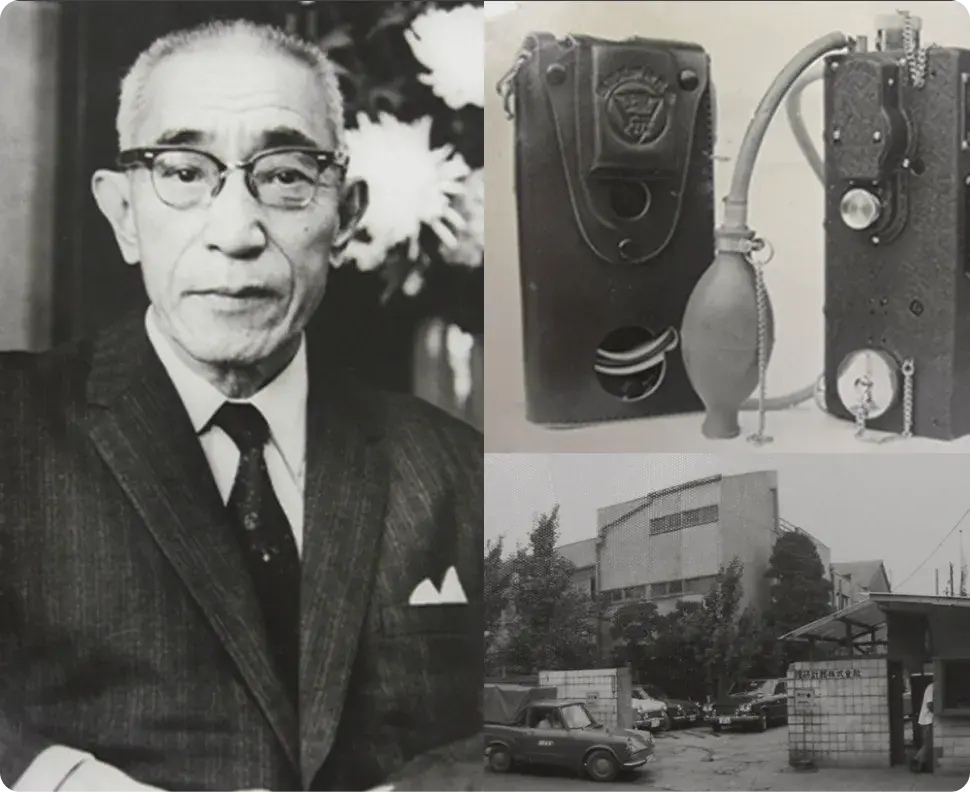

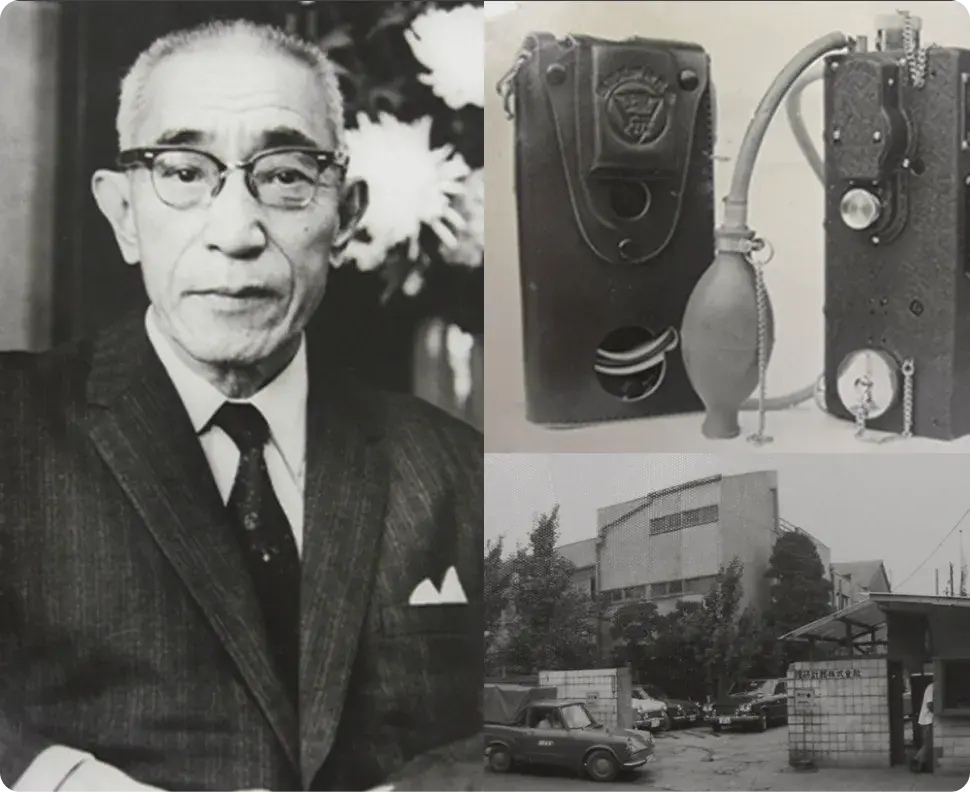

Why Customers Choose Us

Since our beginnings in 1939, Riken Keiki has continued to lead the way in gas detection technology, laying the foundations that support our modern society.

Discover why customers continue to choose Riken Keiki, the global standard in gas detection equipment.

See Our Solutions in Action!

See Our Solutions in Action!