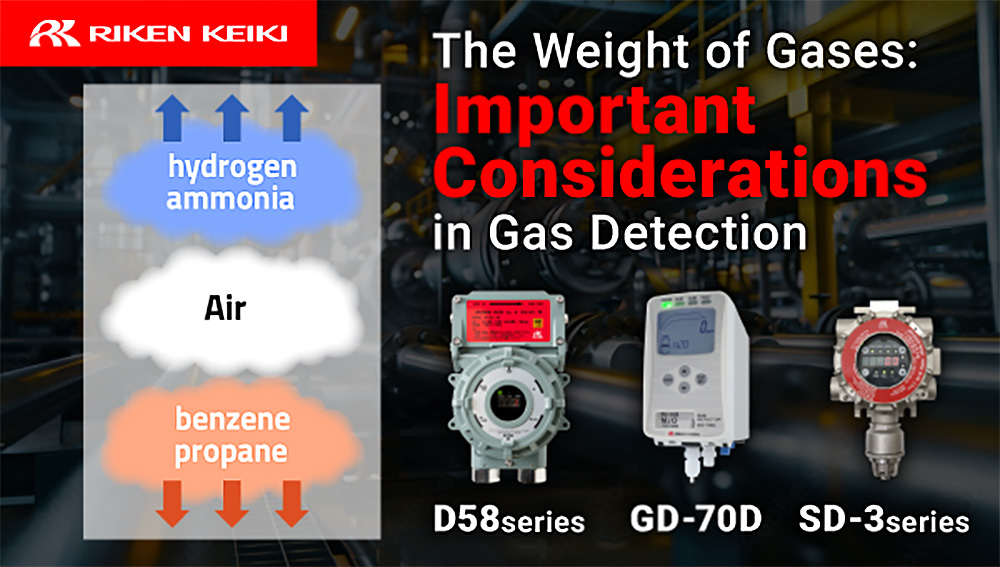

The Weight of Gases: Important Considerations in Gas Detection

Table of Contents

Types of Gas Detectors

There are two primary kinds of gas detectors: fixed gas detectors, which are intended for permanent continuous monitoring in work environments, and portable gas detectors, which are designed to be carried or worn by workers as they move about. In this article, we will discuss the importance of considering the weight of gases to be detected when deciding where to install a fixed gas detector.

First things first, we would like to clarify what we mean by fixed gas detector. By fixed gas detector, we mean any gas detection equipment that is installed permanently at a specific location in the work environment for the purpose of continuously monitoring gas levels in the air. For example, in a plant which uses propane gas as a fuel, it is vital to monitor the presence of any gas leaks from the distribution pipes. The fixed gas detector detects the presence of a gas via a built-in sensor, which is used in conjunction with an indicator/alarm unit and external buzzer to ensure worker safety. Gas comes into contact with the sensors in one of two ways, either by diffusion or by suction. Diffusion-type gas detectors detect gas that comes into contact with the sensor as it spreads throughout the air. Suction-type gas detectors, on the other hand, use a built-in pump to draw in the surrounding air, allowing them to detect the presence of gas further away from the detector.

What is the Specific Gravity of a gas?

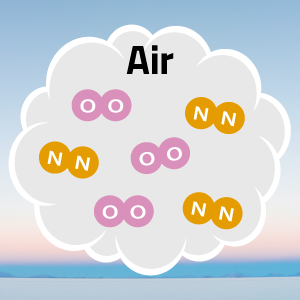

When choosing the right gas detector for your needs, it is important to consider factors such as the properties and location of the gas(es) you want to detect, as well as their concentration and the location where the gas detector will be installed. It is essential to select the right gas detector and the appropriate location, and this cannot be done without considering the weight of the gas(es) to be detected. In the same way that ice placed in a glass of water will float rather than sink, some gases will float to the top of a room when released into the air. This occurs because each type of gas has a different weight.

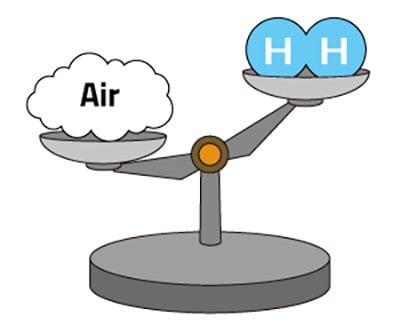

To better understand the weight of gases, a concept known as specific gravity is used. Specific gravity indicates whether a gas is heavier or lighter than air. Air is given a specific gravity of one, and other gases are given a numeric specific gravity relative to air. In other words, if the specific gravity of a gas is greater than one it is heavier than air, and if it is less than one it is lighter than air. Gases with a specific gravity greater than one tend to settle and accumulate near the bottom of a space, whereas those with a specific gravity less than one tend to float and accumulate toward the top of a space.

Atomic Weight and Molecular Weight

Detecting Lighter Gases

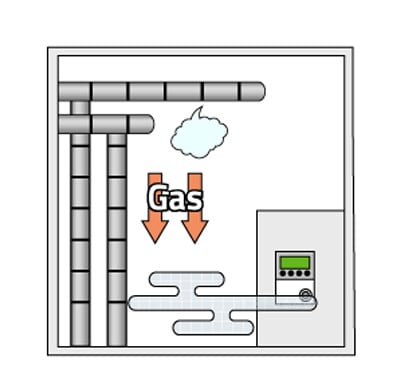

Detecting Heavier Gases

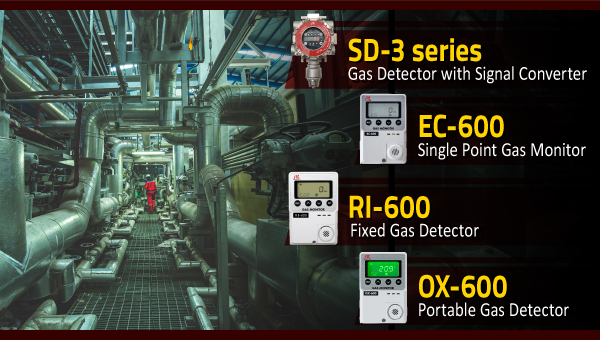

Our Solutions

Suction Type

➡D58 Series, GD-70D

D58 Series: These fixed gas detectors feature an explosion-proof construction and large flow rate pump built in.

GD-70D: This lineup of smart fixed gas detectors can detect over 260 different gases. Ideal for non-explosion proof areas such as research laboratories or cleanrooms.

➡SD-3 DRI/RP-D58

SD-3 Diffusion-type gas detectors meet various international standards (including proposed standards) and can be used together with the RP-D58 explosion-proof pump unit or an aspirator unit as a sampling system. Perfect for use in a wide range of applications, even for monitoring under strict conditions (desired standards, environmental conditions, etc.) or in elevated spaces.

Diffusion Type

This lineup of fixed single-gas detectors offers three power supply options: AC, DC and dry battery. The dry battery type in particular does not require installation work, translating into reduced initial costs. Can be used together with a remote sensor (sold separately) which allows for placing the sensor at a distance of up to 20 meters.

PRODUCTS

Product type |

Fixed Gas Detector |

|---|---|

Applications |

|

single/multi |

Single |

Product type |

Fixed Gas Detector |

|---|---|

Applications |

|

single/multi |

Single |

Product type |

Fixed Gas Detector |

|---|---|

Applications |

|

single/multi |

Single |

Product type |

Fixed Gas Detector |

|---|---|

Applications |

|

single/multi |

Single |

Product type |

Fixed Gas Detector |

|---|---|

Applications |

|

single/multi |

Single |

Want to hear from an expert?

You may also be

interested in

The Importance and Key Considerations of IP Codes When Choosing Gas Detectors

Learn why IP codes matter when choosing gas detectors. Discover how dust and water resistance ensure reliable performance and worker safety in harsh environments.

Heavy Fuel Oil and LNG

Heavy fuel oil powers global shipping with efficiency, affordability, and safety—maximizing cargo space and enabling long-distance voyages.

Gas Monitoring for a More Sustainable Society

Riken Keiki aids sustainability with gas monitors, supporting circular economy efforts and eco-friendly manufacturing practices.

Publications

.png)

.jpg)

.png)