Solutions for Efficient Methanation

Table of Contents

Overview of Methanation

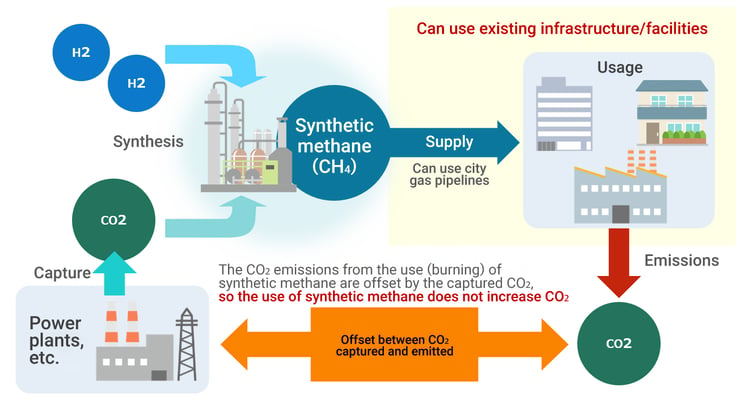

Methanation is a technology that synthesizes methane by reacting carbon dioxide (CO₂) with hydrogen. The interest in this synthetic methane is driven by environmental issues related to greenhouse gases.

Methane is the main component of natural gas, which is effectively utilized in the existing energy infrastructure. However, the carbon dioxide released when burning fuel gases such as methane and natural gas, has long been recognized as a major contributor to greenhouse gases.

This is where synthetic methane, produced through methanation, comes into play. By using CO₂ captured from sources like power plants and factories, the amount of CO₂ released when burning methane can be offset by the amount of CO₂ captured (used) for the production of synthetic methane. As a result, net greenhouse gas emissions can be reduced to virtually zero. This makes methanation a promising approach for achieving carbon neutrality.

**Carbon neutrality: Achieving a balance between CO₂ emissions and their removal.

Methanation Process

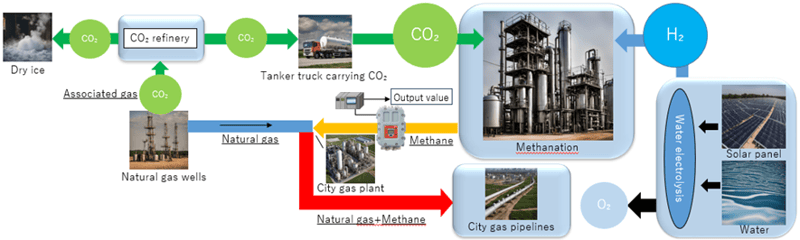

The methanation process is largely divided into three steps:

- Supply of carbon dioxide and hydrogen

- Methane synthesis

- Methane gas supply

1. Supply of Carbon Dioxide and Hydrogen

2. Methane Synthesis

3. Methane Gas Supply

Relationship Between Methanation and Gas Monitoring

As previously mentioned, it is crucial to monitor methane concentration during methanation to ensure appropriate operating conditions. So, how should gas concentrations be measured in a methanation plant?

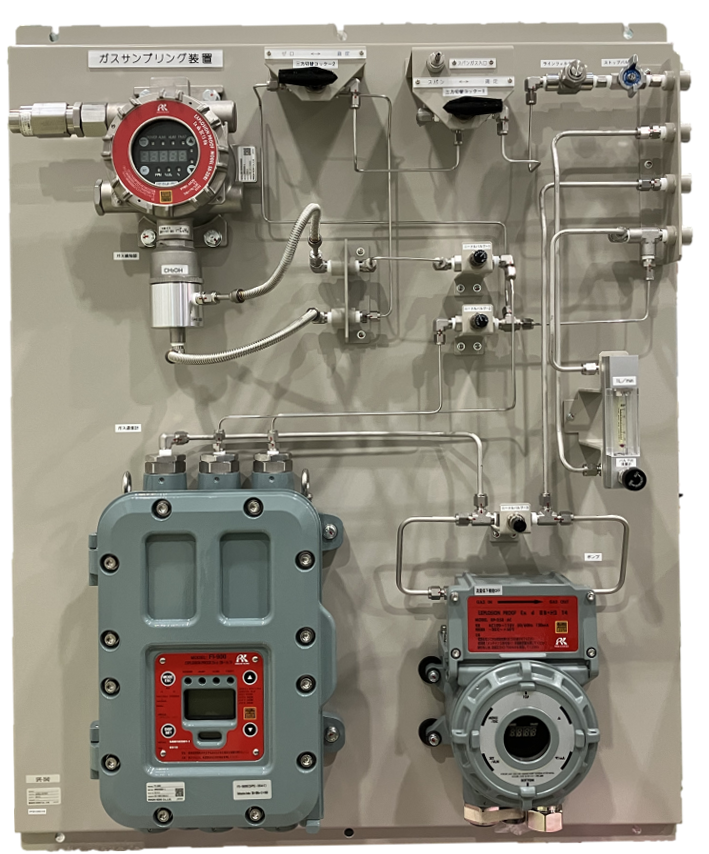

One option is to periodically measure the concentration using gas chromatography. However, since the gas continuously flows through the plant and its concentration constantly fluctuates, near real-time measurement is required, but gas chromatography cannot provide real-time measurements. Additionally, the gas obtained through methanation contains various gases, including methane, so the concentrations of multiple gases must be measured simultaneously.

Riken Keiki Products Optimized for Accurate Methanation

In addition to methanation, Riken Keiki offers various solutions for reducing greenhouse gases, including:

- Controlling hydrogen co-firing turbines

- Monitoring ammonia synthesis and decomposition processes

- Controlling co-firing of natural gas and ammonia

- Monitoring flare gas concentrations

- Monitoring steel gas composition ratios

If you have challenges measuring various gases or need to optimize your measurement environment, feel free to contact us.

PRODUCTS

Want to hear from an expert?

You may also be

interested in

The Importance and Key Considerations of IP Codes When Choosing Gas Detectors

Learn why IP codes matter when choosing gas detectors. Discover how dust and water resistance ensure reliable performance and worker safety in harsh environments.

Heavy Fuel Oil and LNG

Heavy fuel oil powers global shipping with efficiency, affordability, and safety—maximizing cargo space and enabling long-distance voyages.

Gas Monitoring for a More Sustainable Society

Riken Keiki aids sustainability with gas monitors, supporting circular economy efforts and eco-friendly manufacturing practices.

Publications