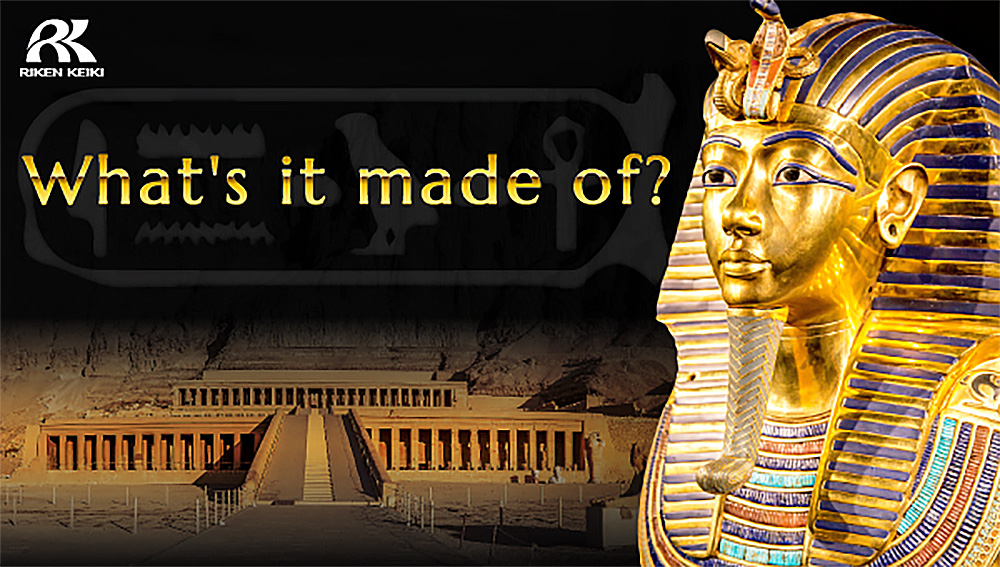

Gases Used in Semiconductor Production

Worksites for Gas Detectors

Why is gas monitoring necessary?

.png)

Assurance

Prevention

Metals

Detection

Our Solutions

HOT TOPICS

Our new multi-point tape type gas detection system is the ideal safety management solution for semiconductor manufacturing processes. The tape detection method offers two main benefits: it leaves traces when gas is detected and has minimal interference from other gases. Additionally, our products feature easy tape replacement, and all tapes have a storage life of 180 days, making them ideal for on-site operations.

RECOMMENDED PRODUCTS

.png)

Want to hear from an expert?

You may also be

interested in

The Importance and Key Considerations of IP Codes When Choosing Gas Detectors

Learn why IP codes matter when choosing gas detectors. Discover how dust and water resistance ensure reliable performance and worker safety in harsh environments.

Heavy Fuel Oil and LNG

Heavy fuel oil powers global shipping with efficiency, affordability, and safety—maximizing cargo space and enabling long-distance voyages.

Gas Monitoring for a More Sustainable Society

Riken Keiki aids sustainability with gas monitors, supporting circular economy efforts and eco-friendly manufacturing practices.

Publications