Riken Keiki's OHC-800 Gas Calorimeter: Demonstrating High Accuracy in a Technology Verification Project by Japan's Digital Agency

Table of Contents

Riken Keiki Co., Ltd. (hereinafter, "Riken Keiki"), has been a leading manufacturer specializing in industrial gas detection and alarm equipment since its establishment in 1939. Our explosion-proof gas calorimeter OHC-800 demonstrated high performance in Japan’s Digital Agency's technology verification project on reviewing analog regulations.

This column will provide a clear overview of the program and explain the distinctive features of Riken Keiki's explosion-proof calorimeter, OHC-800.

Background and Purpose of the Digital Agency's Review of Analog Regulations

The Japanese Digital Agency is working to review analog regulations to foster a society that facilitates the creation of innovative technologies and services. One reason for Japan's stagnant real GDP and income growth compared to Western countries is the delay in digitalization, with analog regulations hindering progress.

The technology verification project that selected Riken Keiki aims to address this issue. In Japan, gas operators are required to measure gas properties, such as calorific value and combustibility, once a day. This project utilized Riken Keiki's explosion-proof gas calorimeter OHC-800 to explore the feasibility of continuous monitoring of gas properties, potentially rationalizing the frequency of daily measurements.

As a result, it was demonstrated that Riken Keiki's OHC-800 can conduct inspections of calorific value and combustibility (Wobbe index, combustion speed) with the same level of accuracy as current gas chromatographs and other methods.

Comparison of OHC-800 and Gas Chromatograph

In the following sections, we will discuss the performance of Riken Keiki's OHC-800. Gas chromatographs (GC) are utilized by gas operators and research institutions for their high precision in gas measurements. However, they require careful maintenance and upkeep, and their complex analysis process means each measurement takes approximately 15 minutes. They are also unable to provide continuous measurements, which is a drawback.

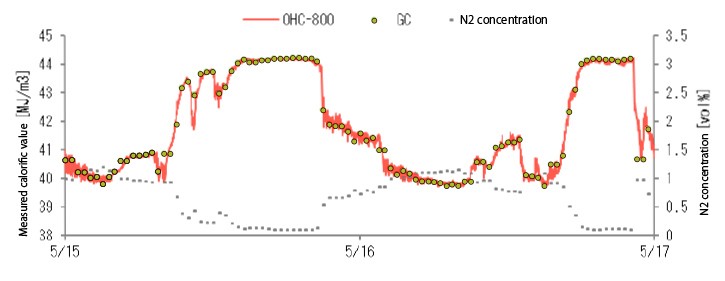

On the other hand, OHC-800 achieves high-precision measurements while eliminating the drawbacks of gas chromatographs. The comparative data for measuring nitrogen-containing fuel gases using OHC-800 and gas chromatograph are shown below:

The green dots on the graph represent the measurement data from the gas chromatograph, while the orange curve represents the measurement data from OHC-800. Since both sets of measurement data align, it indicates that OHC-800 has equivalent accuracy to the gas chromatograph.

Furthermore, OHC-800 can perform continuous measurements, allowing it to capture subtle changes that cannot be measured by a gas chromatograph.

Additionally, there is little difference in the measurement results between the two, even with fluctuations in N2 concentration. In other words, one of the strengths of OHC-800 is its resistance to influences from non-combustible gases, such as N2.

Based on the above, we can summarize the differences between OHC-800 and gas chromatographs as below.

Basic Specifications of OHC-800

The OHC-800 features two physical sensors: an optical sensor and a sonic sensor. The decision to incorporate two sensors stems from challenges observed in conventional calorimeters that use only one.

Typical calorimeters using either an optical sensor or a sonic sensor alone can measure the calorific value of fuel gases consisting solely of paraffinic hydrocarbons. However, when the fuel gas contains components such as N2, CO2, O2, and CO, these substances act as interfering gases, causing errors in the output.

One discovery by Riken Keiki led to solving this issue.

Riken Keiki compared the errors encountered by the optical sensor and the sonic sensor from interference gases and discovered that the error ratio remained consistent regardless of the gas type. By applying this principle to measurements, they successfully eliminated the measurement errors inherent in the two physical sensors.

Riken Keiki coined the term "Opt-Sonic Calculation" (patented) based on the discovered principle. This is also the secret behind OHC-800's capability to achieve high-precision measurements using two physical sensors.

Furthermore, due to its unique mechanism for measuring calorific value, OHC-800 offers four distinctive advantages.

Advantage 1: High Precision

Advantage 2: Continuous Measurement

Advantage 3: High-Speed Response

Advantage 4 of OHC-800: Low Operating Costs

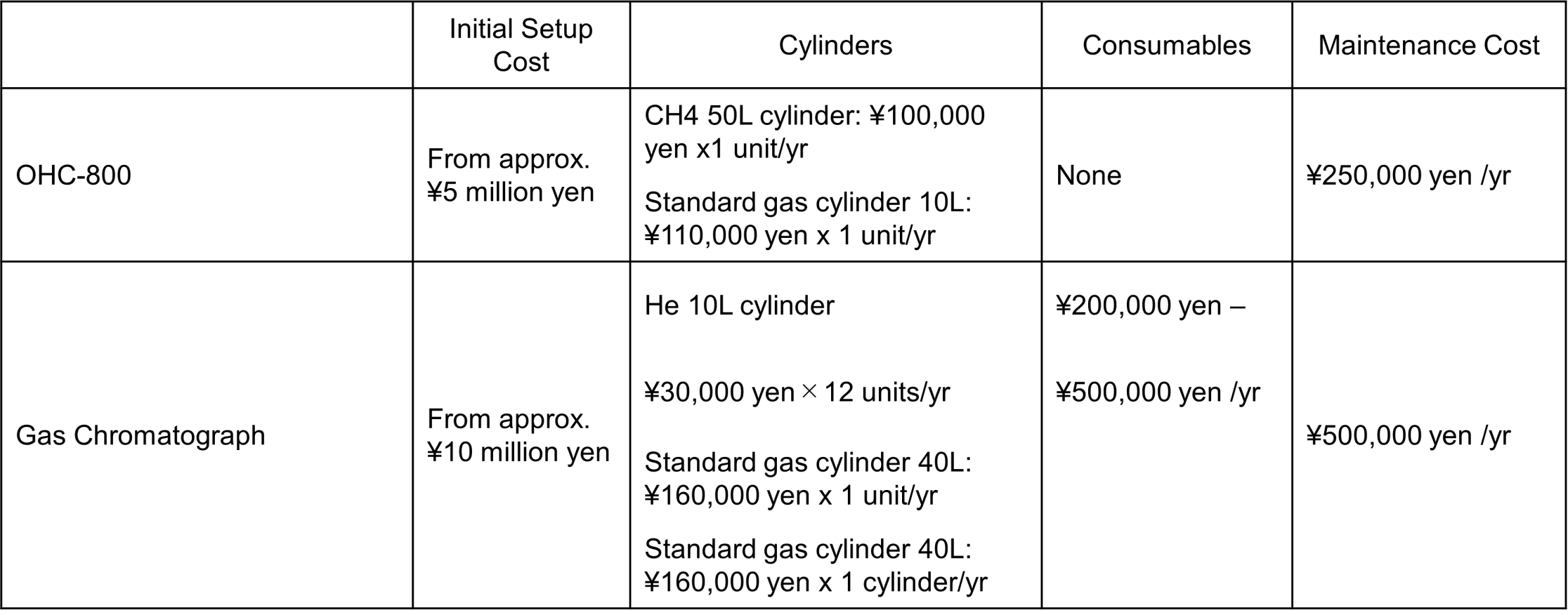

The two physical sensors used in OHC-800 are durable, resistant to contamination, and do not require carrier gas for each measurement, unlike gas chromatographs. Instead, they use reference gases such as instrument air, pure nitrogen, or pure methane, which are inexpensive and readily available. This feature helps reduce running costs and maintenance workload.

Here's a comparison list of initial setup costs and operating costs between OHC-800 and gas chromatographs.

※ Based on Riken Keiki’s findings

The annual operating cost for OHC-800 is approximately 460,000 yen, while a gas chromatograph incurs annual costs ranging from approximately 1.22 to 1.52 million yen. Additionally, it's noteworthy that the initial setup cost for OHC-800 is less than half of that for a gas chromatograph.

OHC-800 Applications

The OHC-800 is installed in a variety of facilities that require calorimetry. Specifically, it is used in petroleum refining, the steel industry, shipbuilding, research laboratories, universities, the food industry, gas companies, turbine manufacturers, and glass manufacturers. Applications include optimizing the air-fuel ratio in turbines and furnaces, adjusting the calorific value of natural gas or LNG vaporized gas, and measuring the calorific value and analyzing the composition of by-product gases in the steel industry.Additionally, Riken Keiki offers a unique real-time gas monitoring system, which combines OHC-800 with the infrared SD-3RI gas detection unit.The features of this real-time gas monitoring system include the ability to continuously measure multiple gas components more easily and safely compared to traditional analyzers. Below are some examples of how this system can address various challenges:

Component analysis of CH₄, H₂, CO₂ (e.g., for controlling methanation)Component analysis of NH₃, H₂, N₂ (e.g., controlling ammonia production, etc.)Component analysis of CH₄, H₂, CO, CO₂, N₂ (e.g., composition analysis of fuel gas from flare stacks and byproduct gases in steelmaking)Monitoring of hydrogen concentration and calorific value during hydrogen co-combustionComponent analysis of methanol and methyl acetate

Based on such value proposals, OHC-800 has a track record of delivering over 200 units to facilities worldwide, including in the Americas, Europe, and Asia.

Digital Agency’s Verification Project Certifies OHC-800's High Accuracy

Businesses with the following needs are encouraged to consider Riken Keiki's OHC-800:

- Monitor unstable calorific values in real-time with high accuracy.

- Perform real-time adjustments of calorific value and air-fuel ratio, responding promptly to feedback.

- Reduce the effort of managing and maintaining partitioned designs used in gas chromatography methods.

- Minimize maintenance challenges associated with gas chromatographs.

PRODUCTS

Product type |

Fixed Gas Analyzer |

|---|---|

Applications |

|

single/multi |

Single |

Want to hear from an expert?

You may also be

interested in

The Importance and Key Considerations of IP Codes When Choosing Gas Detectors

Learn why IP codes matter when choosing gas detectors. Discover how dust and water resistance ensure reliable performance and worker safety in harsh environments.

Heavy Fuel Oil and LNG

Heavy fuel oil powers global shipping with efficiency, affordability, and safety—maximizing cargo space and enabling long-distance voyages.

Gas Monitoring for a More Sustainable Society

Riken Keiki aids sustainability with gas monitors, supporting circular economy efforts and eco-friendly manufacturing practices.

Publications